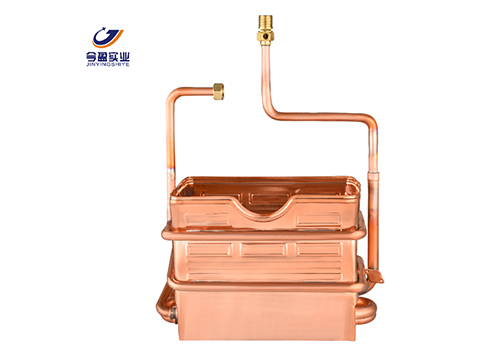

Gas Geyser Gas Water Heater Heat Exchanger

Reasons for choosing a gas geyser heat exchanger:

The Gas Geyser exchanger (heat exchanger), with its high-quality oxygen-free copper material, innovative heat exchange design,

efficient performance, convenient installation and maintenance features, as well as outstanding safety and environmental protection advantages,

has become an ideal core component for medium and large-sized water heater exchanger. As a manufacturer of oxygen-free copper water heat exchangers,

we are committed to providing high-quality and cost-effective products for purchasers and water exchanger producers.

This Gas Water Heater heat exchanger not only helps manufacturers create more competitive water exchanger products, but also brings significant economic benefits and environmental value to purchasers.

Choosing a Gas geyser heat exchanger means choosing an efficient, reliable and sustainable future.

Application scenarios and market value(water heater):

The Gas Geyser exchanger boiler heat exchanger is suitable for a variety of application scenarios, including home heating, hot water supply for large apartments,

and heating needs in small commercial places. Its rated power can easily handle high-load operation and ensure stable heat output. For wall-hung boiler manufacturers,

the high efficiency and reliable durability of this heat exchanger can enhance the overall quality of the product and meet the market demand for high-performance wall-hung boilers. For purchasers,

the energy-saving features and low maintenance costs of heat exchangers can effectively reduce the operating expenses after purchase, while enhancing the satisfaction of end users,

thereby strengthening the market competitiveness of the products.

Safety: (gas geyser heat exchanger )Reliable quality assurance:

Safety is the top priority in the design and production of gas water heater heat exchanger. The gas geyser heat exchanger strictly follows the ISO 9001 quality management system during the manufacturing process, and every gas water heater heat exchanger production link undergoes precise quality inspection. Before leaving the factory, gas geyser (water heater) heat exchanger must pass multiple strict tests, including pressure resistance tests (with a maximum working pressure of up to 3.0 MPa), leakage tests and high-temperature resistance tests, to ensure their safe operation under various extreme conditions. In addition, the structural design of the heat exchanger fully takes into account the requirements of explosion-proof and leak-proof, providing all-round safety guarantees for the water exchanger system. Purchasers and manufacturers can rest assured to choose this heat exchanger and be confident of its stability and reliability in practical applications.